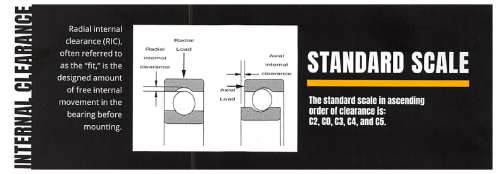

Internal clearance in ball and roller bearings refers to the amount of movement that occurs between the inner and outer rings when one is fixed. This small but crucial space allows for smooth operation by accommodating the motion of rolling elements. The right amount of clearance can significantly impact a bearing's performance, lifespan, and overall efficiency. Understanding internal clearance is essential for selecting the right bearing for your application. In this article, we'll explore what internal clearance is, why it matters, and how to choose the correct clearance for your needs. Internal clearance plays a key role in the performance and longevity of a bearing. It determines whether the rolling elements move with pure rolling or start to slide, which affects mechanical efficiency and heat generation. Proper clearance ensures even load distribution, reduces noise, and helps control vibration levels. There are two main types of internal clearance: Radial clearance is calculated by subtracting the average raceway diameter of the inner ring from the outer ring and then adjusting for the ball size. Axial clearance is generally about ten times the radial clearance. These values are critical for proper bearing function. The ideal internal clearance should be as small as possible—often just a few microns after assembly. However, the exact amount depends on several factors, such as: Bearings come with different clearance grades depending on their intended use. Two common options are C0 and C3: Emerson Bearing has been a trusted name in the bearing industry for decades. We specialize in manufacturing high-quality, precision-machined bearings for a wide range of applications—from industrial machinery to high-speed equipment. Our product line includes ball bearings, ceramic bearings, roller bearings, linear motion bearings, and super precision bearings. Whether you need standard or custom solutions, we’re here to help. Visit our Contact Us page or fill out our Request a Quote form today. Let us support your operations with the precision and quality you deserve. Radiator For VOLVO,VOLVO Radiator,VOLVO Water Cooling Radiator,Car Radiators For VOLVO Guangzhou Casselin Trading Co., Ltd. , https://www.casselinautoparts.comWhy Is Internal Clearance Important?

How Much Clearance Should You Use?

Choosing the right clearance ensures optimal performance, minimizes wear, and extends the life of the bearing. Too little clearance can cause excessive friction and overheating, while too much may lead to instability and reduced precision.

Related Reading:

C0 vs. C3 Clearance: What’s the Difference?

C3 clearance provides more space for expansion without compromising performance, making it suitable for demanding applications. Understanding the difference between these grades helps you select the best bearing for your specific needs.

Choose Emerson Bearing for Precision and Reliability

Bearing Internal Clearance

Radiator For VOLVO,VOLVO Radiator,VOLVO Water Cooling Radiator,Car Radiators For VOLVO Guangzhou Casselin Trading Co., Ltd. , https://www.casselinautoparts.com