904L stainless steel material

Stainless Steel 904L is a high-performance austenitic alloy known for its exceptional corrosion resistance across a wide range of environments. It contains a unique combination of elements that enhance its durability, especially in harsh chemical and marine conditions. The presence of nickel, molybdenum, and copper gives it superior resistance to pitting, crevice corrosion, and stress corrosion cracking, making it ideal for applications where other steels might fail.

Table of contents

- Stainless Steel 904L Chemical Composition

- SS 904L Mechanical Properties

- Physical properties of INOX AISI 904L

- AISI 904L Welding Process

- SUS 904L Mean Coefficient of Thermal Expansion

- Corrosion Resistance of Alloy 904l

- Corrosion Rates of 904L Material

- Chemical Compatibility of Stainless Steel Alloy 904L

- UNS N08904 Material Temperature Range

- Type 904L Stainless Steel Thermal Properties

- AISI 904L Equivalent grades

- Specifications of SUS 904l Material

- SAE 904l Electrical Properties

- Din 1.4539 Applications

- Advantages & Disavntages of SS 904l Material

- Hot Forming of SUS 904l

- Cold Forming of SS 904L

- Machining of Stainless Steel Alloy 904L

Stainless Steel 904L Chemical Composition

SS 904L Mechanical Properties

| Grade | Yield Strength 0.2% Proof (MPa) min | Tensile Strength (MPa) min | Elongation (% in 50mm) min | Hardness | |

|---|---|---|---|---|---|

| Brinell (HB) | Rockwell B (HR B) | ||||

| 904L | 220 | 490 | 36 | 150 | 70-90 typical |

Physical properties of INOX AISI 904L

| Density | kg/dm³ | 8 |

|---|---|---|

| Modulus of elasticity | GPa | 195 |

| Thermal Capacity | J/kg°C | 450 |

| Electrical resistivity | µΩm | 1 |

| Thermal conductivity | W/m°C | 15.8 |

Alloy 904L Offers Excellent Formability and Weldability

As a non-magnetic material, 904L is highly formable and easy to weld, allowing it to be shaped into various forms without losing its structural integrity. This makes it a popular choice in industries that require complex shapes and reliable performance under challenging conditions.

AISI 904L Welding Process

- TIG

- MIG

- SMAW

- PAW

- SAW

SUS 904L Mean Coefficient of Thermal Expansion

| Yield Strength 0.2% Offset psi (MPa) | Ultimate Tensile Strength psi (MPa) | Hardness | Elongation in 2 in. % | ||

|---|---|---|---|---|---|

| 31,000 | 220 | 71,000 | 490 | 70 – 90 Rockwell B | 36 |

1.4539 Material is Known for Its Corrosion Properties

This low-carbon, high-alloy austenitic stainless steel is specifically designed for use in aggressive environments. With its high copper content, it outperforms standard chrome-nickel alloys in sulfuric, phosphoric, and acetic acid solutions. It also shows strong resistance to pitting in chloride environments and is less prone to stress corrosion cracking.

Corrosion Resistance of Alloy 904l

- Good Resistance to Uniform Corrosion

- Temperatures up to 95°F (35°C)

- Concentration Range of 0 to 100%.

- A Nickel content of 25%, 904L is a good Alternative

- Susceptible to Chloride Stress Corrosion Cracking

- 904L Have Good Resistance to SCC

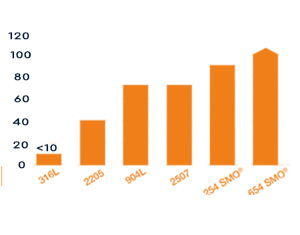

Minimum Stress For Failure % of Rp0.2 at 200°C

Typical threshold stresses determined using the drop evaporation test.

Temperature, °C

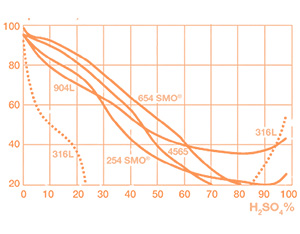

Isocorrosion curves 0.1 mm/year, in pure sulphuric acid.

Corrosion Rates of 904L Material

| Uniform corrosion | Corrosion, (mm/year) |

|---|---|

| pickling acid at 25°C | 0.47 |

| wet process Phosphoric acid at 60°C | 1.2 |

| Distillation of Tall oil at 253°C | 0.06 |

SUS 904L Has High Concentrations of Chromium, Nickel and Molybdenum

Its high alloyed composition ensures excellent corrosion resistance, with nickel and molybdenum contributing to good resistance against chloride stress corrosion cracking, pitting, and general corrosion.

Chemical Compatibility of Stainless Steel Alloy 904L

| Chemical | Compatibility |

|---|---|

| Sulfuric Acid (Hâ‚‚SOâ‚„) | Good resistance ; avoid concentrated acid. |

| Hydrochloric Acid (HCl) | Better resistance compared to many other stainless steels, especially at lower temperatures. |

| Nitric Acid (HNO₃) | Good resistance, particularly up to 65% concentration at room temperature. |

| Phosphoric Acid (H₃PO₄) | Good performance in moderate concentrations and temperatures. |

| Sodium Hydroxide (NaOH) | Resistant, especially in lower concentrations |

| Sodium Chloride (NaCl) | Resistant but prone to stress corrosion cracking in high chloride environments. |

| Acetone | Generally compatible. |

| Ethanol | Generally compatible. |

| Formic Acid | Shows good resistance. |

| Oxidizing Agents | Resistant to many oxidizing agents. |

| Hydrogen Sulfide (Hâ‚‚S) | Susceptible to stress corrosion cracking, especially under high temperature. |

SS 904L is Heat Resistant Alloy Designed for High Temperature Structural Applications

It is suitable for use in high-temperature and corrosive environments due to its excellent thermal and corrosion resistance properties. This makes it an ideal material for industries such as chemical and petrochemical sectors where both heat and chemical exposure are common.

UNS N08904 Material Temperature Range

| Temperature Range | Performance |

|---|---|

| Cryogenic Temperatures (< -200°C / -328°F) | Generally suitable |

| Ambient to Moderate Temperatures (up to ~400°C / 750°F) | Excellent performance |

| High Temperatures (~400°C to 800°C / 750°F to 1470°F) | Capable of withstanding moderate temperatures |

| Exceeding 800°C / 1470°F | The material is generally not recommended for such high temperatures. |

Type 904L Stainless Steel Thermal Properties

| Thermal Properties | Metric | English |

|---|---|---|

| CTE, linear | 15.3 µm/m-°C Temperature 20.0 – 100 °C |

8.50 µin/in-°F Temperature 68.0 – 212 °F |

| 16.5 µm/m-°C Temperature 20.0 – 400 °C |

9.17 µin/in-°F Temperature 68.0 – 752 °F |

|

| 18.2 µm/m-°C Temperature 20.0 – 800 °C |

10.1 µin/in-°F Temperature 68.0 – 1470 °F |

|

| Specific Heat Capacity | 0.460 J/g-°C | 0.110 BTU/lb-°F |

| Thermal Conductivity | 11.5 W/m-K Temperature 20.0 °C |

79.8 BTU-in/hr-ft²-°F Temperature 68.0 °F |

| 12.9 W/m-K Temperature 100 °C |

89.5 BTU-in/hr-ft²-°F Temperature 212 °F |

Refer 904L Material Equivalent, Composition and Specification

Understanding equivalent grades helps users identify the same material across different standards, facilitating international trade and ensuring consistent performance. The chemical composition determines the mechanical and corrosion-resistant properties of the material, while specifications define its suitability for various applications.

AISI 904L Equivalent grades

| Grade | UNS No | Old British | Swedish SS | Euronorm | ||

|---|---|---|---|---|---|---|

| En | BS | No | Name | |||

| 904L | N08904 | – | 904S13 | 2562 | 1.4539 | X1NiCrMoCuN25-20-5 |

Specifications of SUS 904L Material

- Trade Names :SS 904L, AISI 904L, INOX 904L, SUS 904L, Stainless Steel 904L, 904L Steel, ASTM 904L

- Benefits :Non-magnetic, Excellent corrosion properties, Good resistance to sulphuric, Excellent formability and weldability

- Temperature Range :850 °C – 1150 °C

- Features :Lower carbon content leads to resistance to sensitization when welded, Increased resistance to chemical attack from acids

SAE 904L Electrical Properties

| Electrical Properties | Metric | English |

|---|---|---|

| Electrical Resistivity | 0.0000952 ohm-cm | 0.0000952 ohm-cm |

| Magnetic Permeability | <= 1.02 | <= 1.02 |

DIN 1.4539 Applications

- Organic Acid Treatment System

- Sea Water Heat Exchanger

- Paper Industry Equipment

- Heat Exchangers

- Condenser Tubes

- Gas Scrubbing Plants

- Pulp and Paper Processing Industries

Advantages & Disadvantages of SS 904L Material

Advantages

- Excellent Corrosion Resistance

- Good Strength and Toughness

- Good Formability & Durability

- It is Non-magnetic in the Annealed Condition

Disadvantages

- Expensive Material

- Not Ideal for Very High Temperatures

- Extremely High-temperature Applications

- Potential for Work Hardening

Hot Forming of SUS 904L

- Working temperatures:1562 – 2102°F (850 –1150°C)

- Forming Techniques:Forging, rolling, or extrusion

- Solution Annealed:1940 – 2084°F (1060 –1140°C).

- Partial Heating or Cooling :below 2012°F (1100°C)

Cold Forming of SS 904L

- Work Hardening: work-hardens significantly, cold working might require intermediate annealing.

- Nitrogen Implies more powerful processing equipment

- Ductile and Forms Easily

Machining of Stainless Steel Alloy 904L

- Makes it less Machinable

- More Challenging due to work hardening

- Using proper tooling and cutting fluids.

We are Personal Care Spray Bottle,Custom Plastic Spray Bottle in China

Continuous sprayer bottle is one of Mist Sprayer Bottle, special design can make spray time to be 3s-5s

Volumes can choose 160ML 200ML 250ML 300ML 500ML 700ML ,also can customized.

Used in hair gel sprayer,disinfectant,glasses cleaning,oil sprayer and cosmetic packaging.

Continuous Spray Bottle,Continuous Hair Spray Bottle,Continuous Mist Spray Bottle,Continuous Spray Water Bottles

NINGBO CRETE PLASTIC CO.,LTD , https://www.crete-sprayer.com