Different Types of Sedimentation Basins in Wastewater Treatment play a crucial role in separating suspended solids and improving the overall efficiency of wastewater treatment systems. Join us at Song Phung Water Equipment as we explore various types of sedimentation basins including horizontal settling tanks, vertical settling tanks, centrifugal settlers, and specialized settling units such as inclined plate settlers. We will also delve into the advantages and disadvantages of each type. Table of Contents A sedimentation basin is an essential component in wastewater treatment systems where suspended solids are separated from the water through gravitational settling. When wastewater enters the basin, the flow rate is reduced to minimize turbulence, allowing heavier particles to settle at the bottom. The clarified water on top is then directed to subsequent treatment stages. Sedimentation basins can remove up to 60%-70% of suspended solids, reducing organic load and enhancing overall treatment efficiency while cutting operational costs. Sedimentation basins play a vital role in wastewater treatment with four primary functions: The effectiveness of sedimentation basins lies not only in their ability to reduce sludge handling costs but also in their potential for resource recovery. Settled sludge can be collected, processed, and reused in various applications, such as organic fertilizer production or energy generation through combustion. This makes sedimentation basins a key contributor to both environmental protection and cost optimization. The working principle of a sedimentation basin relies on the natural process of gravity-induced settling of solid particles that are denser than water. As wastewater enters the basin, the flow velocity is slowed down to minimize turbulence, giving suspended particles enough time to settle at the bottom. The clarified water on top is then collected and sent to further treatment stages. Key stages of sedimentation basin operation include: Depending on their design and operational principles, different types of sedimentation basins are employed in wastewater treatment systems. Below are some common examples: Horizontal settling tanks have a rectangular shape, with wastewater flowing horizontally from one end to the other. Due to these benefits, horizontal settling tanks are commonly used in primary or secondary treatment facilities at large-scale wastewater treatment plants. Centrifugal settlers utilize centrifugal force to separate solid particles from water, often used in systems requiring rapid processing or dealing with heavy particulate matter. Vertical settling tanks have a cylindrical shape, with water moving upward from the bottom. Vertical settling tanks are widely used in small-scale systems or areas with limited space. These tanks combine flocculation and sedimentation processes, where small particles in the water aggregate into larger flocs before settling. Such tanks are typically employed in systems aiming to remove phosphates or heavy metals. These settlers improve the sedimentation process by increasing the surface area available for particle settling and optimizing water flow distribution. Inclined plate settlers feature tilted plates that increase the settling area and shorten settling time. Tube settlers use multiple parallel tubes to enhance settling performance. Horizontal pipe settlers employ horizontal pipes to extend contact time between water and settling surfaces. Through this article, we’ve explored various types of sedimentation basins in wastewater treatment. Understanding the different types of sedimentation basins helps optimize processes and improve treatment outcomes. For more detailed guidance, feel free to reach out to Song Phung Water Equipment for quick and effective support. >> Learn More: Semi Automatic Pipe Cutting Machine Semi Automatic Pipe Cutting Machine,Cold Pipe Cutting Machine,Tube Pipe Cutting Machine,Manual Pipe Cutting Machine Zhangjiagang heshun machinery manufacturer co.,ltd. , https://www.hsformer.comWhat is a Sedimentation Basin?

The Role of Sedimentation Basins in Wastewater Treatment

How Does a Sedimentation Basin Work?

Different Types of Sedimentation Basins in Wastewater Treatment

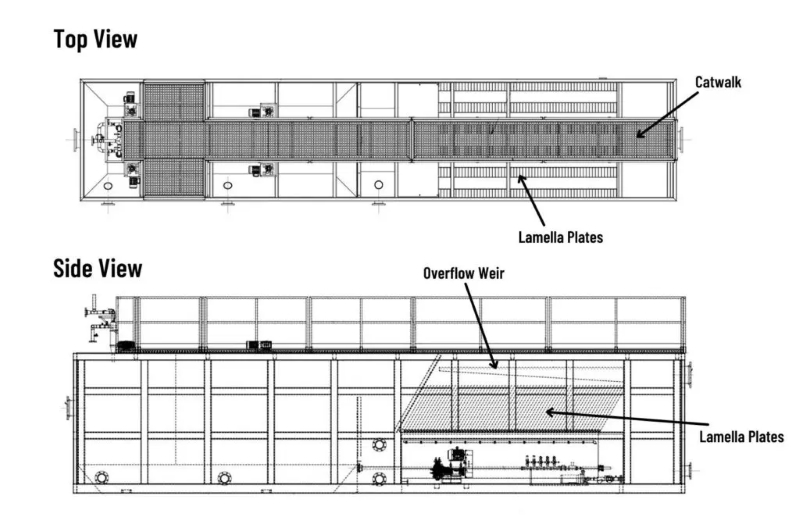

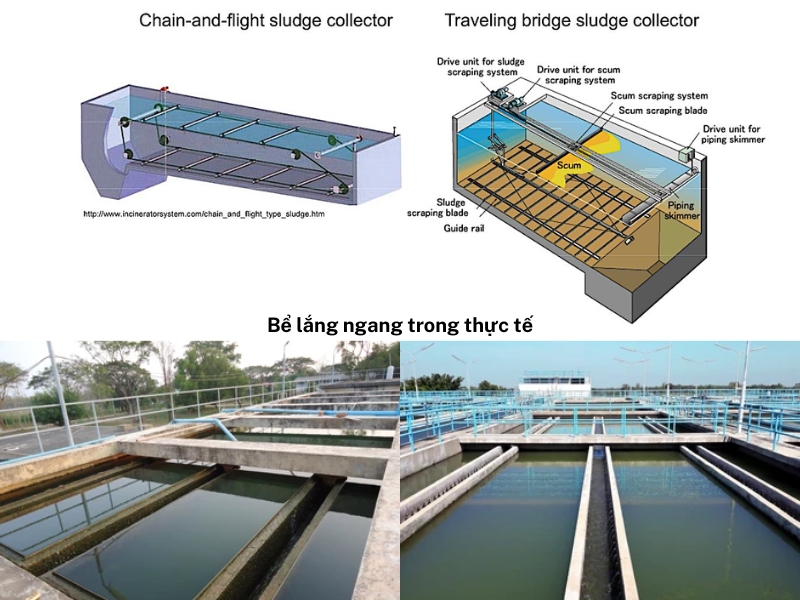

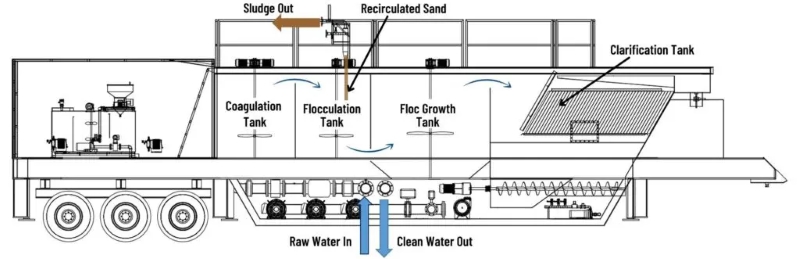

Horizontal Settling Tanks

Centrifugal Settlers

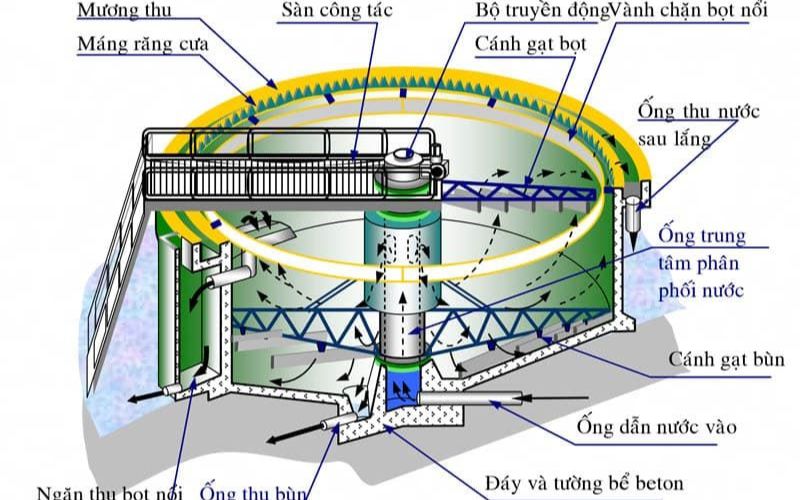

Vertical Settling Tanks

Combined Flocculation-Sedimentation Tanks

Inclined Plate, Tube, and Horizontal Pipe Settlers