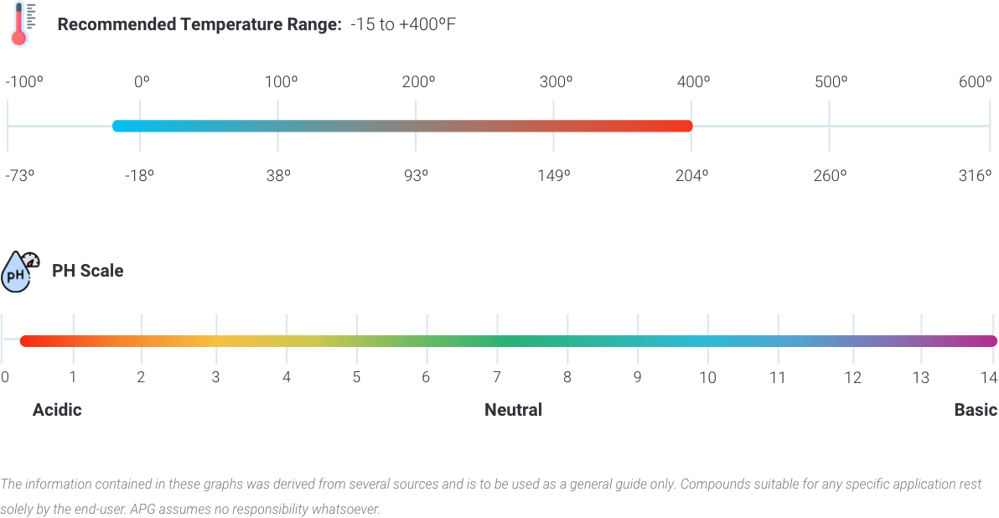

Trade Names: Viton (E.I. DuPont), Fluorel (3M) Fluoroelastomer rubber, commonly known as Viton, is a high-performance material that excels in various challenging environments. It offers excellent resistance to a wide range of oils, petroleum products, ozone, weather conditions, high vacuum, and extreme temperatures. This makes it ideal for use in sealing applications such as gaskets, O-rings, and pump seals. Its outstanding resistance to petroleum-based substances and low compression set make it a preferred choice for handling and transporting fuels, chemicals, and other aggressive media. Additionally, Viton exhibits broad chemical compatibility, making it a versatile option across multiple industries. Harsh Conditions Viton is a fluoroelastomer that performs exceptionally well under extreme conditions, including high temperatures, exposure to harsh chemicals, and high-oxygen environments. It is highly resistant to abrasion, tearing, and degradation, which makes it an ideal material for critical components like O-rings and gaskets used in demanding industrial settings. Beyond its mechanical strength, Viton also demonstrates strong chemical resistance, making it a go-to material in sectors such as automotive, aerospace, and chemical processing. Its reliability and durability ensure long-term performance even in the most challenging applications. Oil & Petroleum The oil and petroleum industry frequently uses Viton due to its excellent resistance to a variety of fluids, including crude oil, gasoline, diesel, hydraulic fluids, and many types of lubricants. It also performs well with vegetable oils and alcohols, making it suitable for a wide range of applications in fuel systems, pumps, and valves. This material’s ability to maintain its integrity when exposed to these substances ensures reliable performance and reduces the risk of leaks or failures. Acetone, Methyl, Organic Acids While Viton is highly resistant to many oils and petroleum products, it is not recommended for use with certain solvents such as acetone, methyl ethyl ketone (MEK), and organic acids. These substances can cause swelling, degradation, or failure of Viton seals and gaskets over time. Therefore, it's important to carefully evaluate the chemical compatibility of Viton with the specific fluids it will be exposed to. In cases where such chemicals are present, alternative materials like nitrile or silicone may be more appropriate. Steel Wire Rope Sling,Stainless Steel Wire Rope Slings,Galvanized Steel Wire Rope Sling,Steel Wire Rope Slings JIANGSU RUIJIN SLING CO.,LTD. , https://www.cnsteelcable.com

Advantages

Disadvantages

Getting to Know: Fluoroelastomer

Steel Wire Rope Sling,Stainless Steel Wire Rope Slings,Galvanized Steel Wire Rope Sling,Steel Wire Rope Slings JIANGSU RUIJIN SLING CO.,LTD. , https://www.cnsteelcable.com